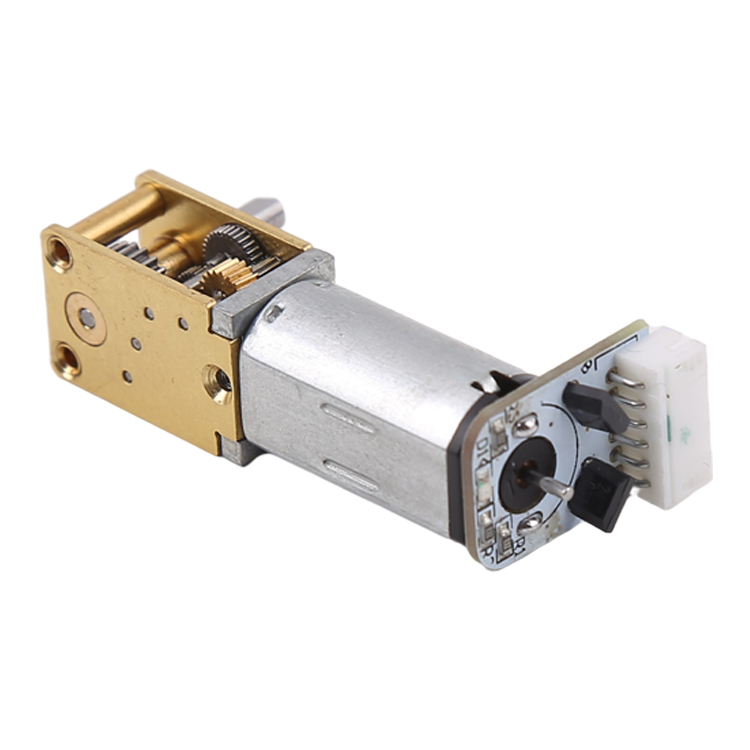

કસ્ટમ એન્કોડર સાથે વોર્મ ગિયરબોક્સ N20 DC મોટર

વર્ણન

આ N20 એન્કોડર સાથેની DC વોર્મ ગિયર મોટર છે.

તે એન્કોડર વિના પણ ઉપલબ્ધ છે.

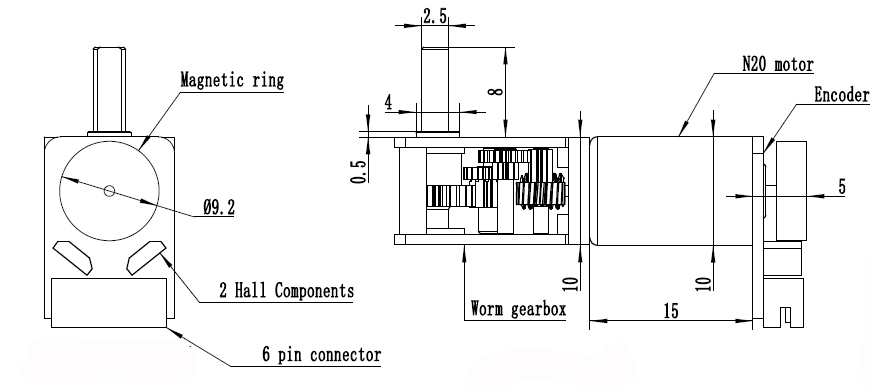

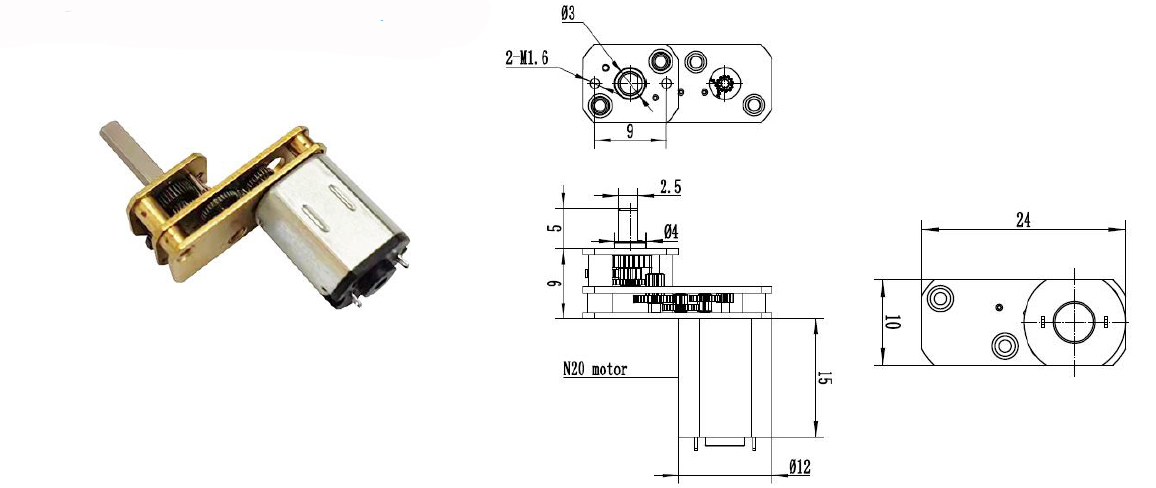

N20 મોટરનો બાહ્ય વ્યાસ 12mm*10mm છે, મોટરની લંબાઈ 15mm છે, અને ગિયરબોક્સની લંબાઈ 18mm છે (ગિયરબોક્સ N10 મોટર અથવા N30 મોટર પણ રાખી શકે છે).

મોટરમાં મેટલ બ્રશ કરેલી ડીસી મોટર હોય છે જેમાં પ્રિસિઝન મેટલ રીડ્યુસર હોય છે. વોર્મ ગિયરનું કદ નાનું અને ગિયર રેશિયો મોટો હોય છે.

ડીસી મોટર ટેકનોલોજી પ્રમાણમાં પરિપક્વ, સસ્તી અને ચલાવવા અને નિયંત્રણમાં સરળ છે. ગિયર બોક્સ સાથે, ટોર્ક ઘણો વધે છે, ઝડપ ઓછી થાય છે, અને તેને નિયંત્રિત કરવું સરળ છે!

નીચેના કૃમિ ગિયરબોક્સ ગિયર રેશિયો ઉપલબ્ધ છે.

૧:૨૧ ૧:૪૨ ૧:૧૧૮ ૧:૨૩૬ ૧:૩૦૨ ૧:૩૯૯ ૧:૫૧૫ ૧:૬૦૩ ૧:૭૯૮ ૧:૧૦૧૬

પરિમાણો

| મોડેલ નં. | N20-1812 વોર્મ ગિયર મોટર |

| કદ | ૧૨ મીમી*૩૩ મીમી |

| ગિયર રેશિયો: | ૧:૨૧~૧:૧૦૧૬ |

| નો-લોડ સીડ (સિંગલ મોટર) | ૫૦૦૦~૮૦૦૦ આરપીએમ |

| એન્કોડર પ્રકાર | મેગ્નેટ હોલ સેન્સર |

| ઠરાવ | ૩ પીપીઆર ૫ પીપીઆર ૭ પીપીઆર ૧૨ પીપીઆર |

ડિઝાઇન ડ્રોઇંગ

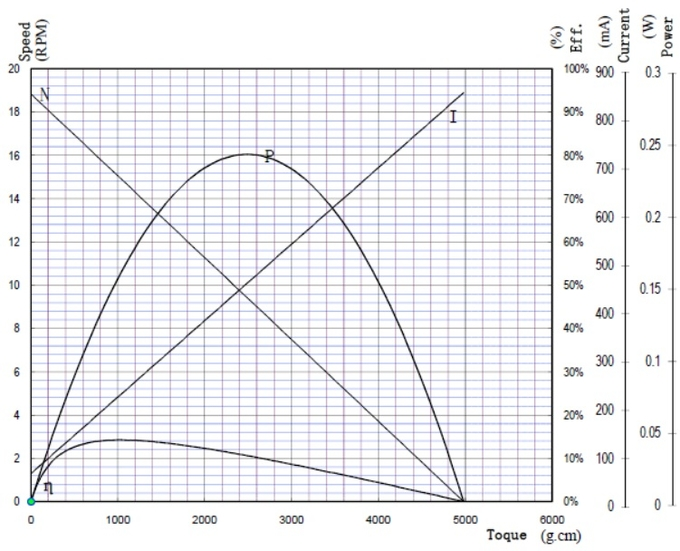

N20 મોટર ટોર્ક અને ગતિ વળાંક

ડ્રાઇવ વોલ્ટેજ બદલતી વખતે, અથવા મોટર વિન્ડિંગ પરિમાણો બદલતી વખતે, મોટરમાં વિવિધ લાક્ષણિકતાઓ હશે, આ વળાંક સંદર્ભ માટે છે.

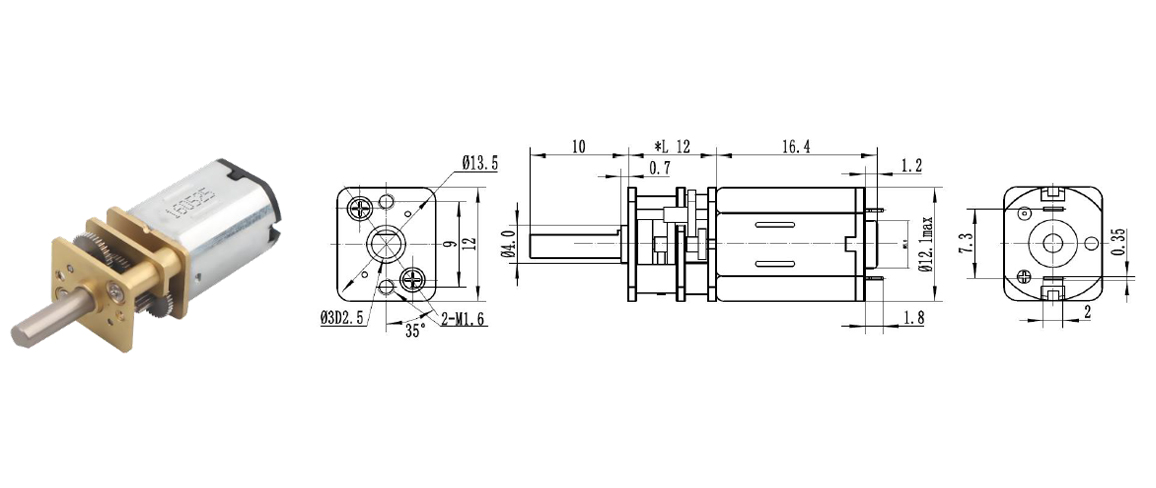

N20 DC મોટરને GB12 ગિયરબોક્સ, 1024GB ગિયરબોક્સ સાથે પણ મેચ કરી શકાય છે, આકૃતિમાં બતાવ્યા પ્રમાણે:

1.N20 DC મોટર + GB12 ગિયરબોક્સ

2.N20 DC મોટર + 1024GB ગિયરબોક્સ

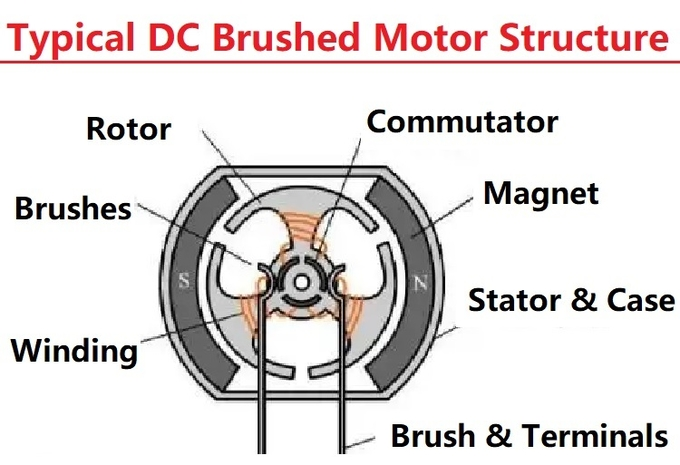

ડીસી મોટર સ્ટ્રક્ચર વિશે

ઉપરોક્ત આકૃતિ ડીસી બ્રશ મોટરની મૂળભૂત રચના દર્શાવે છે.

આ પ્રકારની ડીસી મોટર સ્ટેટર, રોટર, બ્રશ અને કોમ્યુટેટરથી બનેલી હોય છે. સ્ટેટર અને રોટર ચુંબકીય ક્ષેત્રોના પરસ્પર ડ્રાઇવિંગ મોટરને ફેરવવા માટે પ્રેરિત કરે છે. જ્યારે તેઓ શરૂ થાય છે અને ચાલે છે, ત્યારે બ્રશનો ભાગ સ્પાર્ક ઉત્પન્ન કરે છે અને ખાસ એપ્લિકેશનોમાં ઉપયોગ માટે યોગ્ય નથી.

બ્રશ અને કોમ્યુટેટરની સંબંધિત હિલચાલ પહેરવામાં સરળ છે, અને સામાન્ય રચના સાથે ડીસી બ્રશ મોટરનો આયુષ્ય સામાન્ય રીતે ખૂબ લાંબો હોતો નથી, સામાન્ય રીતે 200~2000 કલાક. જે ગ્રાહકો પાસે મોટર માટે આયુષ્યની કડક આવશ્યકતા હોય છે, તેમના માટે સ્ટેપર મોટર પસંદ કરવાની ભલામણ કરવામાં આવે છે.

ડીસી બ્રશ મોટરના ફાયદા

1. ઝડપી ગતિ

2. નાનું કદ

3. ઉચ્ચ કાર્યક્ષમતા (સ્ટેપર મોટરની તુલનામાં)

૪. સાર્વત્રિક ઉપયોગ

5. કનેક્ટ કરવા માટે સરળ અને ઉપયોગમાં સરળ

6. સસ્તું

અરજી

ઇલેક્ટ્રિક ડીસી વોર્મ ગિયર મોટર્સનો ઉપયોગ મુખ્યત્વે બારીઓ, ઘરગથ્થુ ઉપકરણો, મોડેલ કાર, મોડેલ રોબોટ્સ, મોડેલ જહાજો, ઔદ્યોગિક એપ્લિકેશનો, DIY એન્જિન, લઘુચિત્ર વિંચ, રિમોટ કંટ્રોલ કર્ટેન્સ, લઘુચિત્ર દરવાજા ખોલનારા, બરબેકયુ ગ્રીલ્સ, ઓવન, કચરાના નિકાલ, કોફી મશીનો જેવા વિવિધ એપ્લિકેશનોમાં થાય છે. , પ્રિન્ટિંગ પ્રેસ, વગેરે.

લીડ સમય અને પેકેજિંગ માહિતી

નમૂનાઓ માટે લીડ સમય:

સ્ટોકમાં સ્ટાન્ડર્ડ મોટર્સ: 3 દિવસની અંદર

સ્ટાન્ડર્ડ મોટર્સ સ્ટોકમાં નથી: ૧૫ દિવસની અંદર

કસ્ટમાઇઝ્ડ ઉત્પાદનો: લગભગ 25 ~ 30 દિવસ (કસ્ટમાઇઝેશનની જટિલતાના આધારે)

નવો ઘાટ બનાવવા માટેનો સમય: સામાન્ય રીતે લગભગ 45 દિવસ

મોટા પાયે ઉત્પાદન માટે લીડ સમય: ઓર્ડર જથ્થાના આધારે

પેકેજિંગ:

નમૂનાઓ ફોમ સ્પોન્જમાં પેપર બોક્સ સાથે પેક કરવામાં આવે છે, એક્સપ્રેસ દ્વારા મોકલવામાં આવે છે.

મોટા પાયે ઉત્પાદન, મોટર્સને પારદર્શક ફિલ્મ સાથે લહેરિયું કાર્ટનમાં પેક કરવામાં આવે છે. (હવાઈ માર્ગે શિપિંગ)

જો સમુદ્ર દ્વારા મોકલવામાં આવે તો, ઉત્પાદન પેલેટ પર પેક કરવામાં આવશે.

શિપિંગ પદ્ધતિ

નમૂનાઓ અને હવાઈ શિપિંગ પર, અમે ફેડેક્સ/ટીએનટી/યુપીએસ/ડીએચએલનો ઉપયોગ કરીએ છીએ.(એક્સપ્રેસ સેવા માટે 5~12 દિવસ)

દરિયાઈ શિપિંગ માટે, અમે અમારા શિપિંગ એજન્ટનો ઉપયોગ કરીએ છીએ, અને શાંઘાઈ બંદરથી શિપ કરીએ છીએ.(દરિયાઈ શિપિંગ માટે 45~70 દિવસ)

વારંવાર પૂછાતા પ્રશ્નો

1. શું તમે ઉત્પાદક છો?

હા, અમે એક ઉત્પાદક છીએ, અને અમે મુખ્યત્વે સ્ટેપર મોટર્સનું ઉત્પાદન કરીએ છીએ.

2.તમારી ફેક્ટરીનું સ્થાન ક્યાં છે?શું આપણે તમારી ફેક્ટરીની મુલાકાત લઈ શકીએ?

અમારી ફેક્ટરી ચાંગઝોઉ, જિઆંગસુમાં આવેલી છે. હા, અમારી મુલાકાત લેવા માટે તમારું ખૂબ સ્વાગત છે.

૩. શું તમે મફત નમૂનાઓ આપી શકો છો?

ના, અમે મફત નમૂનાઓ આપતા નથી. ગ્રાહકો મફત નમૂનાઓ સાથે ન્યાયી વર્તન કરશે નહીં.

૪. શિપિંગ ખર્ચ કોણ ચૂકવે છે? શું હું મારા શિપિંગ એકાઉન્ટનો ઉપયોગ કરી શકું?

ગ્રાહકો શિપિંગ ખર્ચ ચૂકવે છે. અમે તમને શિપિંગ ખર્ચ જણાવીશું.

જો તમને લાગે કે તમારી પાસે સસ્તી/વધુ અનુકૂળ શિપિંગ પદ્ધતિ છે, તો અમે તમારા શિપિંગ એકાઉન્ટનો ઉપયોગ કરી શકીએ છીએ.

5. તમે MOQ શું છો? શું હું એક મોટર ઓર્ડર કરી શકું?

અમારી પાસે MOQ નથી, અને તમે ફક્ત એક જ નમૂનાનો ઓર્ડર આપી શકો છો.

પરંતુ અમે તમને થોડી વધુ ઓર્ડર આપવાની ભલામણ કરીએ છીએ, ફક્ત તમારા પરીક્ષણ દરમિયાન મોટરને નુકસાન થાય તો, અને તમે બેક-અપ લઈ શકો છો.

૬. અમે એક નવો પ્રોજેક્ટ વિકસાવી રહ્યા છીએ, શું તમે કસ્ટમાઇઝેશન સેવા પ્રદાન કરો છો? શું આપણે NDA કરાર પર હસ્તાક્ષર કરી શકીએ?

સ્ટેપર મોટર ઉદ્યોગમાં અમારી પાસે 20 વર્ષથી વધુનો અનુભવ છે.

અમે ઘણા પ્રોજેક્ટ્સ વિકસાવ્યા છે, અમે ડિઝાઇન ડ્રોઇંગથી લઈને ઉત્પાદન સુધી સંપૂર્ણ સેટ કસ્ટમાઇઝેશન પ્રદાન કરી શકીએ છીએ.

અમને વિશ્વાસ છે કે અમે તમારા સ્ટેપર મોટર પ્રોજેક્ટ માટે થોડી સલાહ/સૂચનો આપી શકીશું.

જો તમે ગુપ્ત મુદ્દાઓ વિશે ચિંતિત હોવ, તો હા, અમે NDA કરાર પર હસ્તાક્ષર કરી શકીએ છીએ.

૭. શું તમે ડ્રાઇવરો વેચો છો? શું તમે તેમનું ઉત્પાદન કરો છો?

હા, અમે ડ્રાઇવરો વેચીએ છીએ. તે ફક્ત કામચલાઉ નમૂના પરીક્ષણ માટે યોગ્ય છે, મોટા પાયે ઉત્પાદન માટે યોગ્ય નથી.

અમે ડ્રાઇવરો બનાવતા નથી, અમે ફક્ત સ્ટેપર મોટર્સ બનાવીએ છીએ.